Hydrostatic vs. Pneumatic Testing: What’s the Difference?

There are two testing methods for hydraulic hose systems: hydrostatic and pneumatic. But what’s the difference? We explain in our brief guide here.

by Scot Ranney • October 11, 2023

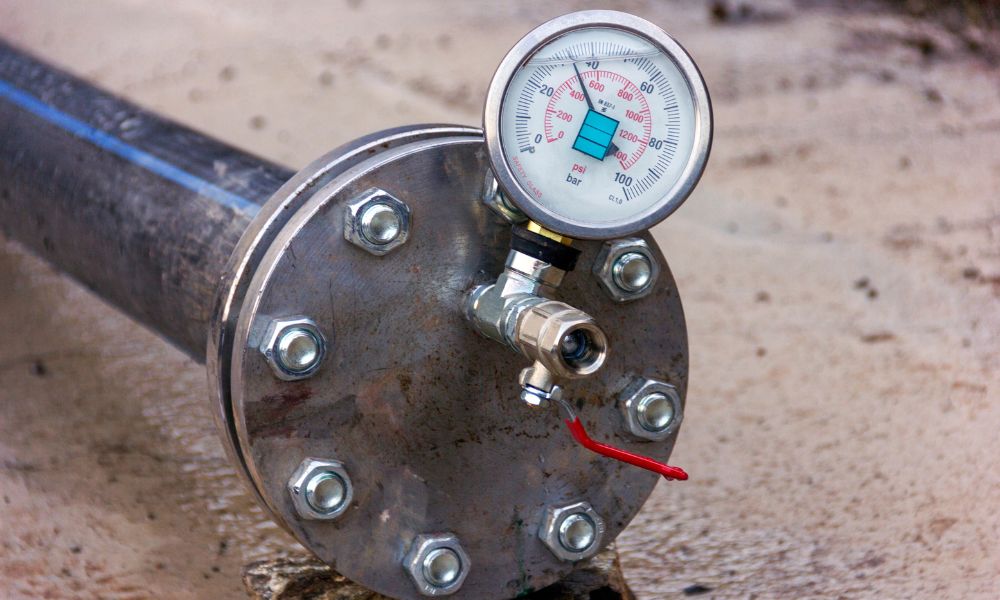

As businesses and industries evolve, reliable and efficient testing methods for equipment and systems are crucial. Two main testing techniques see use across various industries, from construction to food service: hydrostatic and pneumatic testing. While they may seem similar, each method has unique benefits and uses. We address the differences between hydrostatic and pneumatic testing so that you can understand the benefits of both hydraulic hose pressure tests.

Hydrostatic Testing: An Overview

The hydrostatic compression test, also known simply as hydrostatic testing, involves using a liquid (usually water) to exert pressure on a vessel or system to evaluate its integrity and strength. The process includes filling the system with water and pressurizing it to a predetermined level, typically corresponding to the maximum allowable working pressure (MAWP). Benefits of hydrostatic testing include:

- Effective detection of leaks and weaknesses in pipes and vessels

- Evaluation of a system’s overall strength and durability

- Minimizing potential damage due to pressure buildup during operation

- Ensuring compliance with industry standards and regulations

Pneumatic Testing: An Overview

On the other hand, Pneumatic testing involves using a gas (typically air or nitrogen) to pressurize a vessel or system. Similar to hydrostatic testing, this method assesses the integrity, strength, and reliability of the system, but it has distinct benefits:

- Faster pressurization and depressurization, leading to reduced testing time

- Reduced need for drying after testing, as it introduces smaller amounts of moisture

- Less susceptibility to temperature changes during the testing process

- In some cases, preferable for specific industries or applications where liquid testing might be unsuitable

The Hose Shop: Your Trusted Partner for Hydrostatic Testing

Now you understand the difference between hydrostatic and pneumatic testing, but where can you find these testing services? The Hose Shop is a leading provider of hydrostatic testing services, offering comprehensive and reliable solutions for businesses spanning various industries. By choosing The Hose Shop for your on-site pressure test needs, you can trust that our experienced and knowledgeable team will provide accurate results and unparalleled customer support.

Whether you require routine testing of your systems or need to ensure compliance with industry regulations, The Hose Shop delivers quality solutions tailored to your specific requirements. To explore how our hydrostatic testing services can benefit your processes and keep your systems operating efficiently, contact The Hose Shop to schedule a consultation and see the difference we can make for your business.