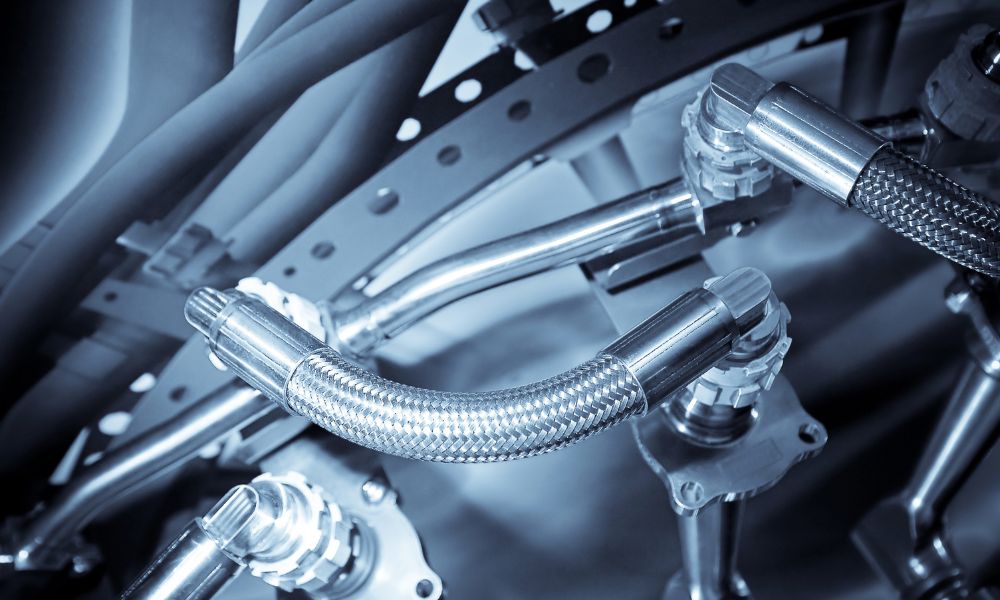

Tips for Preventing Corrosion in Hydraulic Hoses

The last thing any hydraulic hose system operator wants is corrosion. Keep your hydraulic lines rust free with these helpful tips from The Hose Shop.

by Scot Ranney • May 22, 2023

Corrosion is one of the biggest problems for hydraulic hose systems and operators. Hydraulic lines with rusty components can contaminate the system and require a full repair and part replacement. Prevent corrosion in your hydraulic hoses with our tips below.

Replace Worn Seals

The biggest contributor to rusty hoses and fittings are leaks and cracks in the seals and fittings. So the primary concern for any hydraulic hose system operator is to replace worn seals with new ones as soon as they find them.

A loose seal naturally causes fluid leaks on the hose, which can quickly become a magnet for corrosion and contaminate the entire system. Once a seal breaks, there’s not much to do besides replace it with a new one immediately before it leaks and becomes a breeding ground for corrosion.

Have Frequent Inspections and Tests

How do you know when to replace worn seals with new ones? You carry out frequent maintenance inspections. Hydraulic hose system inspections are tests that are vital to stay ahead of major leaks and pinpoint defects and failures before they become significant issues. You want to catch leaks before they let out enough fluid for corrosion to occur.

Maintenance and quality tests for the system, such as on-site hydrostatic pressure tests, are valuable ways to pinpoint minor leaks and defective seals at maximum pressure before they grow into more harmful cracks and defects.

Use Additives

Along with frequent maintenance and repairs, another strategy to keep corrosion out of a hydraulic hose system is to use additives. Various additives, such as anti-wear hydraulic oil and rust inhibitors, can be effective tools. They prevent fluid breakdown and acid formation, which leads to corrosion.

They’re easy to use—you just put the additives in the fluid system—and could extend your hydraulic hoses’ lifespan.

Install Breather Filters

Our last tip for preventing corrosion in hydraulic hoses is to install breather filters in the system, specifically the reservoir. A breather filter on a reservoir keeps the foreign particles that are significant causes of corrosion from entering and the fluid contaminant free.

Breather filters with water vapor removal devices keep the water formation inside the reservoir from contaminating the fluid in the hoses and causing corrosion. But hydraulic hoses operators must replace these filters frequently according to their recommended schedule. Otherwise, they won’t help much after a few months.

Conclusion

We hope our guide helps keep your hydraulic hose system rust free. If you need new hose parts or custom hydraulic lines, visit The Hose Shop. We have everything you need for your hydraulic hose system. Contact our staff with further questions or browse our online inventory today.