5 Ways To Know When To Replace a Hydraulic Hose

How do owners know when it’s time to replace a hydraulic hose? We explain the key warning signs of a hydraulic hose that needs replacement here.

by Scot Ranney • March 20, 2023

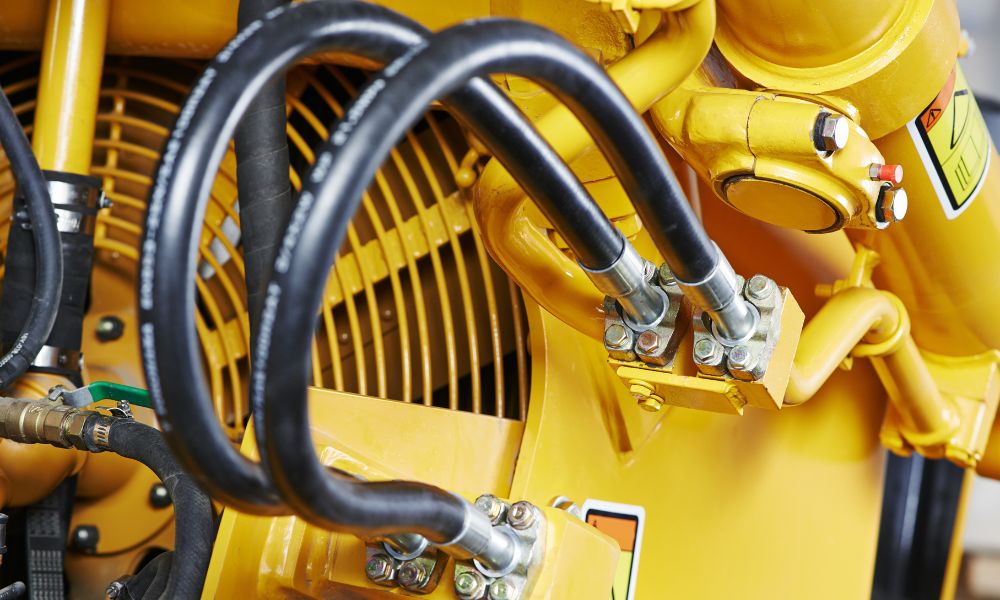

A damaged or degraded hydraulic hose can cause significant harm to an industrial hose assembly and the entire system, which is why owners need to repair or replace them before it’s too late. Below, we explain some of the best ways to know when to replace a hydraulic hose and avoid further problems with the system.

Extensive Damage

The most obvious and credible sign that a hydraulic hose replacement is necessary is that the current hose has extensive damage. For example, it may have significant abrasions. If the hydraulic hose is old or hasn’t had proper care, its rubber can wear out and lead to a pressure buildup, ultimately resulting in a crushed hose.

If a hose with extensive damage appears during an inspection, you should pause the system and replace it immediately, as it can cause more damage to the system or even harm someone.

Oil Leaks

Another clear way to know when to replace a hydraulic hose is to look for noticeable stains or leaks in the hose or around the fittings. Obviously, no owner wants a hose in their system to leak oil, as it’s inefficient, uneconomical, and dangerous to the rest of the assembly and employees.

That’s why it’s paramount that businesses and hydraulic hose system owners conduct regular inspections to search for any signs of leaks that can quickly cause severe and expensive damage if left unchecked.

Corroded or Cracked Fittings

If an oil leak is in a hydraulic hose, there’s a good chance there’s also a corroded or cracked fitting. A corroded fitting is a significant problem and should undergo replacement immediately. You should also pinpoint and fix the cause of the corrosion.

The hose could have worn out after many years, but if it’s still relatively new, it has likely rusted due to a nearby leak. There’s no reason to replace a hydraulic hose if it’s also going to rust from a leak, so conduct a close inspection of the entire assembly and surrounding area to find any other problems before replacement.

Kinks and Twists in the Hose

While a kink or twist in the hydraulic hose assembly may not seem significant, it can indicate more substantial issues. If a hydraulic hose has a kink, it’s likely due to incorrect routing and the hose having a bend radius below the manufacturer’s specification.

If you find a kinked or twisted hose, you should check for damage to ensure it can still perform. If the hose is still in decent shape, reroute it immediately to avoid further kinks or replace it if it has suffered too much harm.

Exposed Wires

Hydraulic hoses are reinforced with wires in the rubber to ensure durability and strength. If exposed wires come up during an inspection of hydraulic hoses, that’s a concerning sign of significant wear on the hose.

It could be environmental factors that have torn away at the wire, but either way, a hydraulic hose with exposed wiring should not be kept in the system. Remove any hose you find with exposed wiring and immediately replace it with reliable hoses.

If you need industrial hose repair or replacement, The Hose Shop can help. Contact our staff to replace a hose or enlist our repair services today.